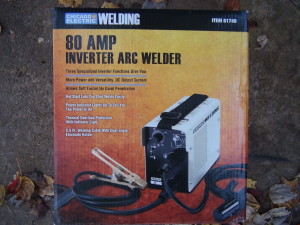

So, for the next step I fabricated a mounting bracket for the bearing out of a piece of quarter angle steel. Once I had the size just right, I drilled two holes for the bearing to mount to it. A couple of one inch bolts and that was secured. Next, I used the overheard strap to hold the steering wheel in the right placement. I already had a few guide marks made where the rod shaft should be. Did I mention that I have never welded anything before? Well, I should have but, that will become obvious here momentarily. I bought a 80 amp inverter arc welder from Harbor Freight Tools. I thought, hey…how hard could this be? I used my sander to clean the area I was going to weld to…previously, I had already cleaned the steel where the bearing was. I rigged up everything on the welder, placed a magnetic ground block near the part I planned to weld was, stuck a Lincoln Electric 6013 electrode stick into the welder, donned my leather gloves, and my welding helmet. Turned the power button on and cranked up the amperage to the full 80 amps. I waited a few minutes for it to heat up (or, do whatever it needed to do) then I carefully tried to weld the joint. As I touched the joint with the 6013 stick, it flashed sparks and then as I tried to move the stick the buzzer went off inside the welding machine and the stick had become fused to the steel I was trying to weld. A few times I was able to pull the stick away, but one time the stick popped completely out of the handle. I was starting to get frustrated for a few reasons; #1 My damn helmet glass was pitch black…how the hell are you supposed to see what you are doing while you are trying to weld? #2 I know the stick acts as flux (in a sense) to melt/join both sides of the steel you are trying to weld but, why did it keep sticking? Was it shorting out somehow? #3 This reason has three parts to it; Here I am essentially building a car (which I have never done before) so that is somewhat exciting yet intimidating. I need to learn how to weld. And, lastly…I need for the welds that I do make be strong enough so they don’t separate while I’m driving the car. Maybe I’m just too hard on myself…but, now it seems I find myself at another stage in this build where I’m a bit frustrated. Does that make sense? The last two photos were taken the next day (11/5)…if you are an experienced welder you can probably spot whatever it was that I did wrong.

Share This:

Comments

comments